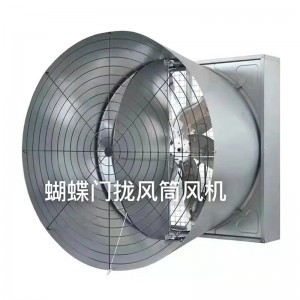

1000mm 36-inch high air volume farm Stainless steel exhaust fan

Details Description:

1. The outer frame is made of 304 stainless steel, which has high strength and strong corrosion resistance(The outer frame material of the fan with the same specification has galvanized plate for selection).

2. Fan blades: 6 pieces of 304 stainless steel fan blades are beautiful and durable. Through the dynamic balance test, the air volume is large, the noise is low, and it is not easy to deform.

3. Pulley: high-strength aluminum-magnesium alloy hot die casting, light weight and high strength

4. The louvers automatically open when the fan is powered on, and automatically close when the power is off, effectively preventing rainwater from entering.

Working Principle:

The exhaust fan is based on the cooling principle of air convection and negative pressure ventilation. It is a kind of natural inhalation of fresh air from the opposite side of the installation site--- door or window, and exhaust the sultry air quickly out of the room. Any problems with poor ventilation can be improved. The effect of cooling and ventilation can reach 90%-97%.

The whole machine adopts CAD/CAM design, which has the characteristics of low investment cost, large air volume, low noise, low energy consumption, stable operation, long service life and high efficiency.The shutter can be opened and closed automatically to prevent dust, water. It is a necessary equipment for ventilation, heat dissipation and heatstroke prevention in animal husbandry, greenhouse and factory workshop.

Technical parameter

| Model NO. | YNH-1000 |

| Dimensions: height * width * thickness(mm) | 1000*1000*400 |

| Blade Diameter (mm) | 900 |

| Motor speed (rpm) | 1400 |

| Air volume (m³/h ) | 30000 |

| Noise decibels(dB) | 70 |

| Power(w) | 550 |

| Rated voltage(v) | 380 |

Other Specification Parameter

|

Model

|

Blade diameter (mm) |

Blade speed (r/min) |

Motor speed (r/min) |

Air volume (m³/h) |

Total pressure(Pa) |

Noise (dB) |

Power (W) |

Rated voltage (V) |

Height (mm) |

Width (mm) |

Thickness (mm) |

|

YNH-800(29in) |

710 |

660 |

1400 |

22000 |

60 |

≤60 |

370 |

380 |

800 |

800 |

380 |

|

YNH-900(30in) |

750 |

630 |

1400 |

28000 |

65 |

≤65 |

550 |

380 |

900 |

900 |

400 |

|

YNH-1000(36in) |

900 |

610 |

1400 |

30000 |

70 |

≤70 |

550 |

380 |

1000 |

1000 |

400 |

|

YNH-1100(40in) |

1000 |

600 |

1400 |

32500 |

70 |

≤70 |

750 |

380 |

1100 |

1100 |

400 |

|

YNH-1220(44in) |

1100 |

460 |

1400 |

38000 |

73 |

≤70 |

750 |

380 |

1220 |

1220 |

400 |

|

YNH-1380(50in) |

1250 |

439 |

1400 |

44000 |

56 |

≤70 |

1100 |

380 |

1380 |

1380 |

400 |

|

YNH-1530(56in) |

1400 |

325 |

1400 |

55800 |

60 |

≤70 |

1500 |

380 |

1530 |

1530 |

400 |

Installation Precautions:

Dear Customer:

First of all, thank you very much for choosing YUENENG fan! In order to ensure the normal operation of the fan, we must pay attention to the following points during installation:

1.When installing the fan, please make sure the fan is in the horizontal position, and it is recommended to use infrared level;

2.The inner side (protective net side) of the fan is flush with the inner wall to ensure that the drainage hole and removable maintenance board of the fan are on the outside of the outer wall, which is convenient for maintenance;

3.After the fan is placed in the hole, insert a wooden wedge into the gap above the middle column, and finally fill the gap with foaming agent ( not recommended to use concrete direct powder to prevent the extrusion deformation of the fan caused by the thermal expansion of the concrete which will affect the use);

In order to prevent the motor from burning out due to phase loss or overload, it is recommended to install breakers on the fan control circuit (Chint, Delixi, Schneider and other brands).

Products categories

-

Phone

-

E-mail

-

Skype

Skype

8618361802039

-

-

WeChat

WeChat

8618361802039

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur